Customer Type: EV Conversion Specialist

Situation

Converting classic cars to electric is complex. Dashboards vary significantly, with design time and quality being vital.

Our client required both hardware and software development – a compact system to interface with the vehicle and multiple different displays, depending on each vehicle project.

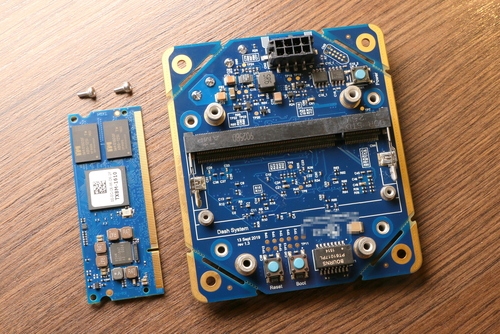

When they engaged Argentum Systems, projected unit volumes were small, making bespoke development costs a concern. The system was to be designed around a System-on-Module, and within very specific dimensions.

Problem

Multiple challenges arose:

Size: Our customer identified the “worst case” unit size, and selected a display for the first EV project – Argentum Systems’ design must fit behind this display.

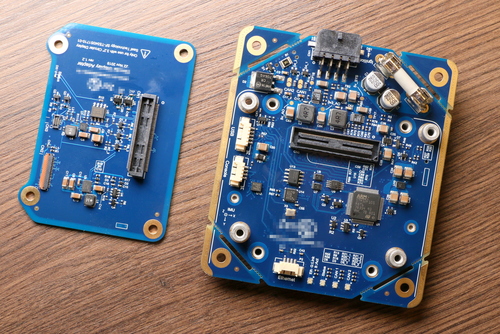

Flexibility: As future conversions occurred, additional displays or uses would be identified by our customer, and support must be added to the system in a cost-effective manner.

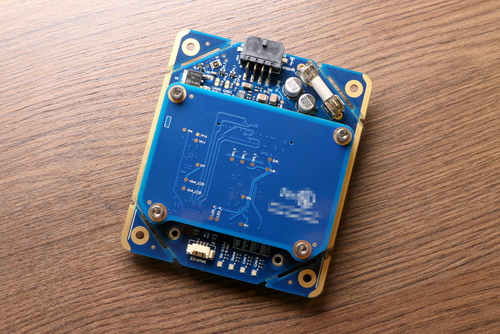

Power: Standby power consumption must be minimised, and the customer mandated support for two CAN buses.

Implication

Balancing the high-performance with low-power constraints required careful component selection. While driving, the high resolution displays must present fluid dashboard graphics to the driver; while the ignition is off, the system must monitor the vehicle’s CAN buses with minimal battery energy.

Due to the uncertainty of future displays or use-cases, adaptability and futureproofing were both major considerations.

Outcome

Argentum Systems designed multiple software and hardware elements for this EV solution, employing both Linux and Zephyr.

Powerful: System-on-Module

Simple: Refitting via a swappable adapter

Enhanced: Power management

Rapid: Cost effective reconfiguration

Since the initial design, Argentum System has adapted the unit to support multiple further displays.